Deer processing cutting boards are the unsung heroes of the hunting and game-processing world. They provide a sturdy and hygienic surface for handling and preparing your hard-earned venison, ensuring that every cut is precise and every meal is safe and delicious.

In this guide, we’ll dive into the world of deer processing cutting boards, exploring the materials, designs, maintenance tips, and accessories that can enhance your game-to-table experience.

Deer Processing Cutting Board Materials

Choosing the right cutting board material is essential for deer processing. Different materials offer unique advantages and disadvantages, so it’s important to select one that meets your specific needs.

Wood

- Advantages:Durable, easy to clean, and provides a good grip for knives.

- Disadvantages:Can harbor bacteria, may stain or warp over time.

Plastic

- Advantages:Non-porous, easy to clean and sanitize, and lightweight.

- Disadvantages:Can dull knives, may scratch easily.

Composite

- Advantages:Combines the durability of wood with the non-porous nature of plastic, providing a long-lasting and easy-to-clean surface.

- Disadvantages:More expensive than other materials.

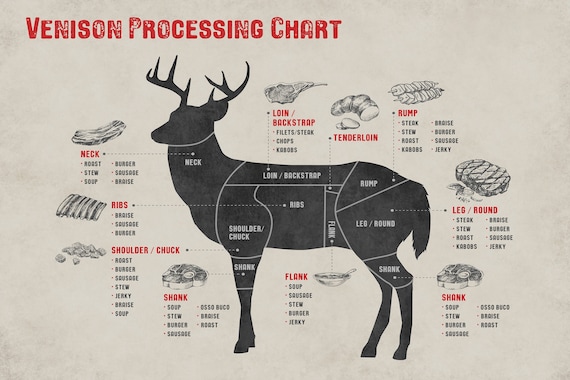

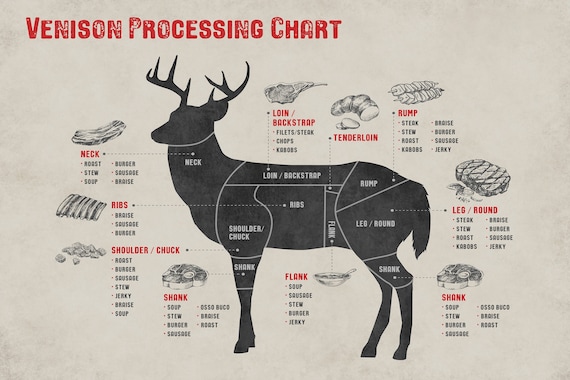

Cutting Board Design

When choosing a deer processing cutting board, consider the size, shape, and thickness that best suit your needs. The size of the board should be large enough to accommodate the size of the deer you are processing, while the shape should provide a comfortable and stable work surface.

The thickness of the board should be sufficient to prevent the board from warping or cracking under pressure.

Deer processing cutting boards are essential tools for any hunter, and choosing the right one is crucial for a successful and safe processing experience. If you’re looking for a cutting board specifically designed for processing 2×2 mule deer , there are several options available that cater to the unique size and shape of these animals.

These boards often feature non-slip surfaces and durable construction to ensure stability and longevity during the processing process.

Specialized cutting boards are designed for specific tasks, such as boning, filleting, and butchering. Boning boards are typically made of a hard material, such as polyethylene or polypropylene, and have a smooth surface that makes it easy to remove bones from meat.

When processing your next deer, make sure to use a cutting board that is specifically designed for the task. These boards are made from durable materials that can withstand the sharp knives used for cutting and boning. Plus, they often have features like non-slip surfaces and built-in grooves to catch blood and juices.

And if you’re looking for a way to attract deer to your hunting area, be sure to check out black widow deer scent . This powerful scent is made from the urine of mature bucks and is proven to attract deer from long distances.

Once you’ve got your deer processed and your hunting area set up, you’ll be ready for a successful hunting season.

Filleting boards are typically made of a softer material, such as rubber or cork, and have a grooved surface that helps to prevent the fish from slipping.

Size

The size of the cutting board you need will depend on the size of the deer you are processing. A small cutting board may be sufficient for processing a small deer, while a larger cutting board will be necessary for processing a large deer.

The cutting board should be large enough to provide a comfortable work surface, but not so large that it is difficult to maneuver.

Shape

The shape of the cutting board you choose will depend on your personal preference. Some people prefer a rectangular cutting board, while others prefer a round or oval cutting board. The shape of the cutting board should provide a comfortable and stable work surface.

Thickness

The thickness of the cutting board you choose will depend on the type of processing you are doing. A thicker cutting board will be more durable and will be less likely to warp or crack under pressure. A thinner cutting board will be lighter and easier to maneuver.

Maintenance and Care

Properly maintaining your deer processing cutting board is crucial for ensuring its longevity and preventing contamination. Regular cleaning and sanitizing will help keep your board free from bacteria and other microorganisms that can compromise the safety of your food.

Here are some tips for cleaning and maintaining your deer processing cutting board:

Cleaning

- After each use, wash the cutting board thoroughly with hot, soapy water. Use a soft-bristled brush to remove any food particles or debris.

- Rinse the cutting board thoroughly with clean water to remove any soap residue.

- Allow the cutting board to air dry completely before storing it.

Sanitizing

- Once a week, or more often if the cutting board is heavily used, sanitize the board using a food-grade sanitizer. Follow the manufacturer’s instructions for dilution and application.

- Allow the cutting board to air dry completely before storing it.

Do not use harsh chemicals

Avoid using harsh chemicals, such as bleach or ammonia, to clean or sanitize your deer processing cutting board. These chemicals can damage the board and make it unsafe for food contact.

Hygiene and Safety

Maintaining proper hygiene is crucial when using a deer processing cutting board to prevent cross-contamination. Bacteria can easily transfer from raw meat to other surfaces, including cooked food or clean utensils. Therefore, it is essential to follow strict guidelines for handling and storing the cutting board to minimize the risk of bacteria growth and ensure food safety.

Proper Handling

*

- *Wash hands thoroughly before and after handling the cutting board, especially after touching raw meat.

- *Clean the cutting board immediately after use with hot soapy water and a disinfectant solution.

- *Avoid using abrasive cleaners or scouring pads, as these can damage the surface of the board and create microscopic crevices where bacteria can hide.

- *Sanitize the cutting board regularly with a food-grade sanitizer to kill any remaining bacteria.

Proper Storage, Deer processing cutting board

*

- *Store the cutting board in a dry, well-ventilated area to prevent moisture buildup, which can promote bacteria growth.

- *Keep the cutting board away from other food items to prevent cross-contamination.

- *If the cutting board is made of wood, it is recommended to oil it occasionally to prevent drying and cracking, which can create crevices for bacteria to hide.

By adhering to these hygiene and safety practices, you can effectively prevent cross-contamination and ensure the safe handling and storage of your deer processing cutting board.

Accessories and Tools: Deer Processing Cutting Board

To enhance the functionality of a deer processing cutting board, various accessories and tools can be utilized. These accessories improve efficiency and safety during the processing process.

Knife sharpeners, cutting guides, and meat trays are essential accessories for deer processing.

Knife Sharpeners

- Sharpening knives regularly is crucial for efficient and safe processing.

- Using a knife sharpener ensures that the knives remain sharp and precise, reducing the risk of accidents.

Cutting Guides

- Cutting guides assist in making precise cuts, reducing waste and ensuring uniform pieces of meat.

- They are especially useful for cutting large cuts of meat, such as roasts and steaks.

Meat Trays

- Meat trays collect and contain meat and juices during processing, preventing contamination and maintaining a clean work area.

- They facilitate easy transfer of meat to storage containers or other processing areas.

Budget and Value

When budgeting for a deer processing cutting board, it’s crucial to consider your individual needs and preferences. The price range for cutting boards can vary significantly depending on factors like size, material, and features.

To determine the appropriate budget, start by evaluating your needs. Consider the size of deer you typically process, the frequency of use, and any specific features you may desire, such as a juice groove or non-slip feet.

Value Proposition

Different cutting boards offer varying levels of value based on their materials, construction, and durability.

- Plastic cutting boards: Budget-friendly, lightweight, and easy to clean, but may not be as durable as other materials.

- Wood cutting boards: Durable, aesthetically pleasing, and naturally antimicrobial, but require regular maintenance and can harbor bacteria if not properly cared for.

- Composite cutting boards: Made from a blend of materials, offering a combination of durability, antimicrobial properties, and ease of maintenance.

Consider the value proposition of each material and choose the one that best aligns with your needs and budget.

User Reviews and Recommendations

When selecting a deer processing cutting board, it’s beneficial to consider the experiences and feedback of other users. Reading online reviews can provide valuable insights into the pros and cons of different products, helping you make an informed decision.

Based on user reviews, highly recommended cutting boards for deer processing include those made from durable materials like high-density polyethylene (HDPE) or polypropylene. These materials are known for their resistance to stains, odors, and bacteria, making them ideal for handling and preparing venison.

Pros and Cons

Pros:

- Durability:HDPE and polypropylene cutting boards are highly durable and can withstand the rigors of deer processing, including cutting through tough bones and joints.

- Hygiene:These materials are non-porous and resistant to bacteria, ensuring a hygienic surface for food preparation.

- Easy to clean:HDPE and polypropylene cutting boards are dishwasher safe, making cleanup a breeze.

Cons:

- Weight:These cutting boards can be heavy, especially in larger sizes.

- Cost:High-quality HDPE and polypropylene cutting boards can be more expensive than other materials.

Recommendations

For deer processors seeking a durable and hygienic cutting board, the following options are highly recommended based on positive user reviews:

- Cabela’s Premium Deer Processing Cutting Board:Made from heavy-duty HDPE, this cutting board provides a large surface area and is designed to handle the toughest cutting tasks.

- Bass Pro Shops XPS Cutting Board:Constructed from durable polypropylene, this cutting board is lightweight and easy to handle, making it a good choice for smaller workspaces.

- Buckstop Deer Processing Cutting Board:Made from food-grade HDPE, this cutting board features a non-slip surface for added safety during use.

Final Review

Whether you’re a seasoned hunter or just starting your journey into game processing, a high-quality deer processing cutting board is an investment that will pay off in both safety and convenience. By choosing the right board for your needs, maintaining it properly, and using it wisely, you can enjoy the fruits of your hunt for years to come.

FAQ Compilation

What are the best materials for deer processing cutting boards?

The best materials for deer processing cutting boards are those that are durable, non-porous, and easy to clean. Popular choices include high-density polyethylene (HDPE), polypropylene (PP), and stainless steel.

How should I clean and maintain my deer processing cutting board?

Always wash your cutting board with hot, soapy water after use. Avoid using harsh chemicals or bleach, as these can damage the surface of the board. For deep cleaning, you can use a food-grade sanitizer.

What are some accessories that can enhance my deer processing experience?

There are a variety of accessories that can make deer processing easier and more efficient, such as knife sharpeners, cutting guides, and meat trays. These accessories can help you make precise cuts, keep your workspace organized, and prevent cross-contamination.